How to Build a Subfloor for a Shed or How to Build a Subfloor for a House Build it with the precision of a fine craftsman, using the time-tested techniques that have been used for hundreds of years. Step-by-step instructions will tell you how to build a strong, sturdy subfloor and not only save money, but ensure that your shed and house will stand the test of time. This easy-to-follow guide contains an illustrated overview on subfloors, plus detailed photos and actual dimensions.

If you are planning on building a shed, first you need to plan out what type of shed you want to build. You can decide based on your needs and the materials that are readily available. After deciding which type of shed you want, now it is time to consider how to build a subfloor for a shed.

How to build a subfloor

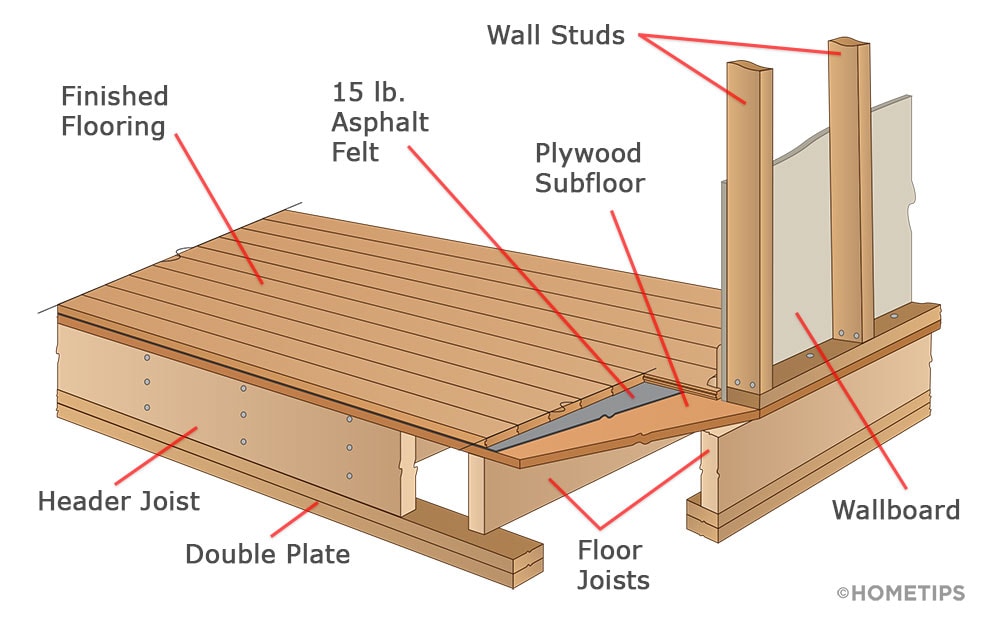

Building a subfloor is a big step in the construction process. It’s the base of your house and what you build on top of it will determine how strong and secure your structure is. The best time to install a floor system is when the house has been framed and braced.

There are several different flooring options when building a shed or cabin; however, all of them should be treated with an approved wood preservative before installation to protect against rot and decay. A pressure-treated wood subfloor may not be necessary in areas where there are no wet conditions or where the ground slopes away from your shed or cabin. You can use either tongue-and-groove solid lumber or plywood as your subflooring material. Both can be stained, painted or left unfinished.

If you’re building a garage or workshop that doesn’t require insulation, you can install 6×6 pressure-treated posts on 16″ centers and nail 2×8 joists on top with post caps at each end (see How to Build a Garage). This type of setup provides enough room for cars and trucks to park underneath. For larger buildings such as garages and workshops.

1. Choose your materials.

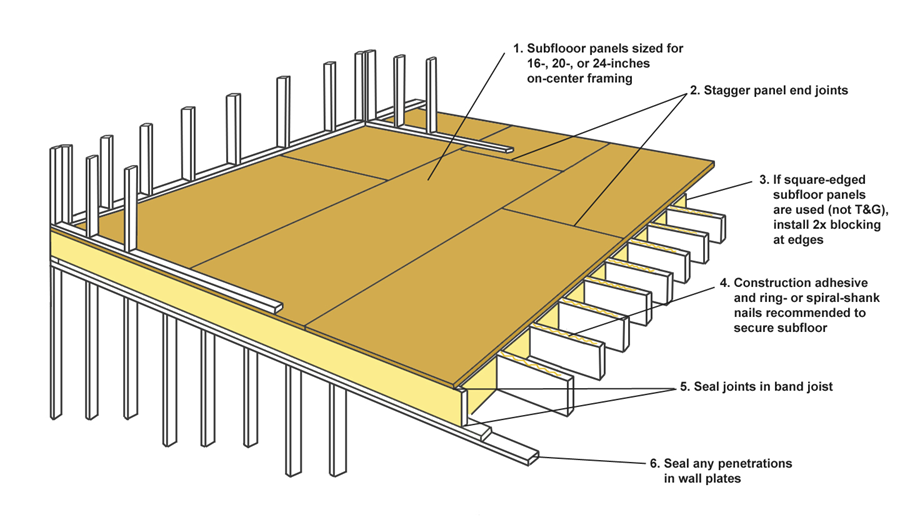

The most common material for subfloors is plywood, but OSB (oriented strand board) or concrete are also options. Plywood is the more expensive option, but it’s also more durable than OSB and has a longer life span.

2. Lay out your subflooring.

Measure and cut each piece of plywood or OSB to fit the area you need to cover with your subflooring. Place the first layer of plywood or OSB down on the ground and secure it using nails or screws at each corner, using at least two screws per corner (four per piece). Make sure that your joints between pieces aren’t too close together — if they’re too close together, moisture can get trapped in between them, causing leaks or mold growth inside your shed or house. Also make sure that your joints aren’t too far apart — too much space between pieces will create weak spots in your flooring that could cause structural damage later on if heavy objects are placed on top of them (such as when you put down flooring inside a shed or house).

3. Continue laying down layers until all of your subflooring has been installed

How to Build a Subfloor for a Shed

A shed subfloor is the floor of your shed. This is made up of two layers: the floor joists and the ceiling joists. The floor joists are what support the weight of the shed while the ceiling joists support its roof. You can build this subfloor with 2×6 inch lumber or 1×6 inch lumber. However, you can add extra strength to it by using plywood underneath it as well.

Step 1 – Laying Out Your Floor Joists

Lay out your floor joists on top of the ground in a rectangular shape that will fit inside your shed frame without overlapping one another. Make sure that these are level with each other so that they will be strong enough to support both the weight of your shed and any snow or rain that may fall on them during winter months or storms.

Step 2 – Marking Out Bare Spots

If there is any bare spot on your floor joists where there isn’t any plywood underneath them yet, mark this spot so you know where to nd more plywood later on when you install your ceiling joist system as well (see below).

A subfloor, or underlayment, is the layer of board material that lies below the final flooring surface. It provides a solid base for the rest of your flooring system, and it helps prevent moisture from getting into your flooring layers. A subfloor also increases the structural strength of your home’s first floor.

A subfloor can be made with either plywood or OSB (oriented strand board). Plywood is made up of thin sheets of wood glued together at right angles. OSB is made out of thin strands of wood aligned parallel to one another and compressed into sheets. Both materials are strong, but OSB is less expensive because it uses less material.

Installing a subfloor involves cutting boards to fit your room’s dimensions and laying them out flat in the desired pattern. Once you’ve laid out your design, you can start nailing down the boards with nails or screws if necessary.

Subfloors are the foundation of your home. Without a strong subfloor, you cannot build a solid structure.

Subfloors are typically made of wood or concrete and serve several purposes:

They provide a flat surface for laying flooring materials.

They support vertical elements like walls and ceiling joists.

They provide insulation between living spaces and the ground.

They help keep moisture out of your basement or crawlspace by acting as an air barrier.

How to Build a Subfloor for a Shed

A subfloor is the foundation of your shed that provides structural integrity and insulation. The subfloor keeps the shed floor from sagging or bowing, which can cause leaks and other problems.

Building a subfloor for a shed is similar to building one for a house. You’ll need to build it strong enough to support the weight of the walls and roof. You’ll also have to make sure it’s level so you don’t have any problems with sagging or twisting.

The first step in building a subfloor is determining what size joists you need and where they should go on the floor plan of your shed. If you’re using 4x4s as studs and planks as rafters, then you’ll want to use 12-inch joists spaced at 16 inches on center (OC). If you’re using 2x6s, then use 9-inch joists spaced at 24 inches OC.

If you’re using pressure-treated lumber, then use galvanized nails to secure the boards together, but if they aren’t pressure treated then use screws instead of nails so they don’t corrode over time and cause wood rot or other problems in the future

A subfloor is the base of your shed that will support the walls, floor and roof. It’s typically made from plywood or OSB (oriented strand board), but you can also use pressure-treated lumber. A subfloor helps provide strength and stability to the structure, which is important when you’re building a shed in an area where there are high winds, heavy snow or extreme temperatures.

The easiest way to build a subfloor is with 2x4s on 16-inch centers. This allows you to get more beams in between studs and provides more room for installing electrical wiring and plumbing lines inside of your shed. You can also use 2x6s on 24-inch centers if you want extra strength in high-wind areas.

You’ll need to use pressure-treated lumber if you live within 50 miles of salt water or if you’re building your shed near an ocean or saltwater creek where there’s a good chance that saltwater runoff could contaminate ground water. Pressure-treated lumber will last longer than untreated wood when exposed to these damaging conditions long term so it’s worth the extra cost upfront if this is an issue where you live

Subfloors are the first layer of your home’s foundation. They provide structural support for the rest of the house, and ensure that your home is strong enough to withstand heavy furniture, appliances and people. The subfloor also keeps moisture from seeping through the entire structure of your house.

A subfloor is typically made from plywood or OSB (oriented strand board), but you can also use concrete blocks or decking boards if you’re working on a wood floor. You can make your own subfloor using 2x4s or 2x6s, but it’s usually easier to buy one pre-made at a lumber yard or home improvement store.

Building a subfloor requires several steps:

1) Level out the ground: Start by leveling out the area where you’ll be building your shed, house or other structure. This will make it much easier to install your subfloor later on in the process. If there are any hills or valleys in the ground, fill them in with sod and rocks so that they level out evenly across the entire area where you’ll be building your shed.

2) Install pressure-treated plywood: While pressure-treated plywood isn’t required for most projects, it does offer some protection against insects and rot

A subfloor is the foundation of a house. It’s the first layer of structural support for the flooring that will cover it. The subfloor is made from plywood or oriented strand board (OSB) and is attached to the joists with nails, screws or bolts.

A subfloor should be at least 1 inch thick for strength and rigidity, and it must extend past the walls by at least 3 inches on all sides to allow for expansion and contraction of your home’s structure over time.

The easiest way to build a subfloor is with OSB. OSB is made up of thin sheets of wood veneer pressed together under heat and pressure with a waterproof glue between them. It’s then covered with another layer of paper that’s glued on top to make it watertight.

To install an OSB subfloor, you’ll need:

12-foot 2-by-4 lumber pieces

16d common nails

A hammer or pneumatic nail gun (optional)

Subfloors are the base for all of your home’s interior walls. If you’re building a house from scratch, you’ll want to lay down a subfloor before you build any walls. But even if you’re just adding on to an existing structure, installing a new subfloor is a good idea because it will make your space look and feel more level and stable. In addition, if your subfloor is old or damaged, replacing it will make your floors easier to clean and maintain.

Before starting this project, determine whether or not your home needs a subfloor. If the ground beneath has dirt or gravel, then it doesn’t require one. However, if you want to install hardwood flooring or carpeting in the future, then installing a subfloor now will make that process easier later on.

Subfloors are typically made out of plywood or OSB (oriented strand board). Plywood is stronger than OSB but can be more expensive as well as heavier to work with due to its thickness — typically 3⁄4 inch thick for most residential applications versus 1⁄2 inch for OSB boards. Both types of wood come in 4×8 sheets that are easy to transport and install by yourself given adequate tools (such as