If you are looking for instructions on how to build a shuffleboard table or a shuffleboard court, the information is right here. Take the time to read the article and the whole process of building one will be truly demystified.

If you do not have a woodworking workshop, or if you just do not have time or desire to build your table , read on. Below you’ll find a step by step process on how to build a shuffleboard table. Not only will we explain to you how it’s done, but we include directions for building a table in case you want to do it yourself.

How to build a shuffle board

The first step in building a shuffleboard court is to determine the right location for it. This is an important part of the process because you will want to make sure that your court is located where there will be enough room for people to play.

The second step is to pick out the proper materials for your court. This can be done by going to your local hardware store and picking out the various items that you need to have in order to build the court. You will also want to consider using a contractor who specializes in this type of construction, as they will be able to help you with any issues that come up during the building process.

The third step is to begin constructing your court by laying down concrete blocks or bricks on top of each other in order to create a solid foundation for your court. Once this has been completed, you can start putting down other materials such as wood planks or asphalt tiles in order to make sure that your shuffleboard court is level and sturdy enough for players.

Step 1: Build the frame.

The frame can be made of wood or metal. Wood is less expensive, but it also requires some maintenance and upkeep. Metal is more durable, but more expensive.

If you choose to use wood, use pressure-treated lumber for durability and longevity. You can find a variety of different types of pressure-treated lumber at your local home improvement store.

If you choose to use metal, it’s best to buy galvanized steel or aluminum since these materials are resistant to corrosion and rusting. You can also find these materials at your local home improvement store or online at sites like Lowes or Amazon.com.

Materials Needed:

Wood: 4x4s or 2x4s (for the legs) and 1/2″ plywood sheets with MDF on one side (for the playing surface). If using small 2x4s in place of larger 4x4s, make sure they’re not warped or bowed, as this could affect the consistency of your shuffleboard court later on down the road!

Metal: Two 24″ x 48″ pieces of galvanized steel or aluminum sheet metal; these will serve as the main playing surface for your shuffleboard table

How to Build a Shuffleboard Table

Shuffleboard is a fun game that can be played by anyone, at any age. You can play the game indoors or outdoors. It’s also a great way to spend time with your family or friends. And you don’t need a lot of space to play–you can even build your own table if you have the space for it.

Building Your Own Table

You’ll need:

– Large sheets of plywood (1/2″ thick)

– Wood glue and screws

– Sandpaper (100 grit) and paintbrush

– Wood stain or paint in desired color(s)

– Paint brush(es)

If you think shuffleboard is just a game for seniors, think again. The sport has been around since the early 1900s, and it’s still going strong, with tournaments and leagues springing up all over the country.

Shuffleboard tables come in many shapes and sizes. Some are designed for home use while others are meant to be commercial grade. Most have built-in scoring systems that record your score as you play.

If you’re interested in building your own table, here are some tips on how to do it:

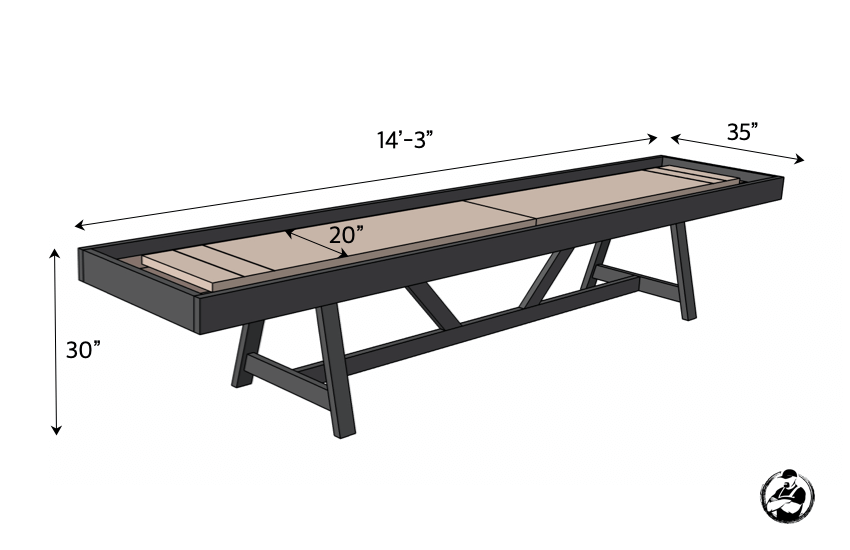

1. Consider how much space you have available for your table. Tables can range from 8 feet long by 2 feet wide to 12 feet long by 3 feet wide (20 x 60 cm x 90 cm). Smaller tables can fit in most rooms (except closets), while larger ones require outdoor spaces such as patios or porches.

2. Make sure your flooring can support the weight of the table and its contents without buckling or warping over time.

3. Use a level surface for best results; this will help keep the balls rolling smoothly along the surface of the table rather than wobbling around until they fall off the end of their path onto the floor below or into another player’s way of play).

Step 1: Prepare the surface

The first thing you want to do is make sure you have a smooth, level surface to work with. The shuffleboard court should be around 8 feet wide by 14 feet long and have a height clearance of between 6 inches and 12 inches.

Step 2: Pour the concrete

After you’ve prepared your surface, it’s time to pour the concrete. You’ll need a mixture of 3 parts sand and 1 part cement — and make sure all materials are washed and dried before mixing. Once you’ve mixed up your batch, you can start pouring it into the court using shovels or scoops.

Step 3: Spread out the concrete evenly

Spread your concrete evenly across the entire court using shovels or scoops so that there are no large clumps or uneven spots. You’ll want to make sure there are no puddles of water at any point in time during this process as well — if there are, just remove them by hand with a trowel or putty knife. Be sure to tamp down any areas where there’s still loose sand or gravel underneath — these will pop up over time as they dry out.

The first step to building a shuffleboard court is the actual floor. It needs to be made of concrete with a smooth, flat surface. The head height should be at least 4 feet, with the length and width being at least 20 feet by 40 feet.

The next step is to install wooden forms along the edges of the shuffleboard court. These forms will help you get the right shape for your shuffleboard table so that it will work properly once it’s finished.

After installing your forms, you can pour your concrete into them using a trowel or shovel. Be sure that you use enough cement so that it fills all of your forms completely and doesn’t leak out anywhere else along the edges or corners.

How to Build a Shuffleboard Court

Shuffleboard is a popular game that has been around for decades. The game is played on a court with four players on each team. Each team member takes turns sliding their discs down the court towards their opponent’s end of the table. The objective of the game is to get as many of your discs into your opponents side as possible before they get yours into theirs. It’s a fun family activity that anyone can enjoy! If you want to learn how to build a shuffleboard court, here’s some tips and instructions on how to do it yourself!

Materials Needed:

Lumber (Make sure you get the right kind for your project)

Nails or Screws

Tools Needed:

Saw (Jig saw, circular saw, etc.)

Drill (Power drill)

A shuffleboard court is a rectangular wooden surface on which shuffleboard players propel disks of varying weights. It is usually about 40 feet long and 10 feet wide, with a slight incline in the middle to help guide the disk towards the end.

A shuffleboard court can be built from scratch or purchased as a kit online. The surface is covered with sandpaper, which can be replaced when needed. A game of shuffleboard requires two people — one on each side of the table — who use their cues to push their disks down the court towards each other’s goal.

There are several ways to build a shuffleboard court:

Sandwich a plywood subfloor between two sheets of 1/2-inch plywood. Screw through all three layers into studs or joists below. Staple carpeting over that layer and add another 1/2-inch layer of plywood over it all, again screwing through all three layers into studs or joists below. Cut holes in this new layer for light fixtures and plumbing lines if necessary (if you’re building this part yourself). Apply a thin layer of concrete base along the entire floor area using a trowel or roller; let dry for 24 hours before continuing with any further steps

The first step to building a shuffleboard court is to decide what material you want the court to be made out of. You can use concrete, metal, or wood. The material you choose will be determined by the area you have available and what your budget is.

The next step is to measure the area that you want the court to be built in. You need enough room for players to walk around the table and for them to stand at each end of the table. This measurement should be taken from one end of the table to the other end with players standing at each end as well as walking around it. Once you have this measurement, subtract 1 foot from it (for every 4 feet) and that will give you an idea of how wide your court needs to be in order for all players on both teams to have room around them during play time.

After measuring your space, it’s time to determine how long your court needs to be so that all players will have enough room when playing on it. You need enough length so that all players have room behind them while they are playing so they don’t run into each other when moving back and forth across their lanes while shooting at their pucks during play time

Building a shuffleboard court is not a difficult project if you follow these simple steps. For help with a large shuffleboard court, see the video at the end of this article.

1. Mark out the court lines with masking tape. The width of the court should be between 4 feet and 6 feet, depending on what kind of playing surface you are using.

2. Cut 16 pieces of 2-by-4 lumber for each side of the court using a circular saw or table saw. Cut each piece to length so that there is about 1 inch left over on either side when it is installed for leveling purposes later on in this process. Use wood glue and nails or screws to attach these pieces together into two walls (one for each side of the court). Make sure there is at least an inch gap between the boards where they meet at 90 degree angles (e.g., where two corners meet).

3. Lay down plastic sheeting over your entire work area so that nothing gets stained by any spills or drips while you are working with paint or stain later on in this process. If you don’t have access to plastic sheeting, then cover everything else up with newspapers or cardboard boxes so that it doesn’t get ruined either way!