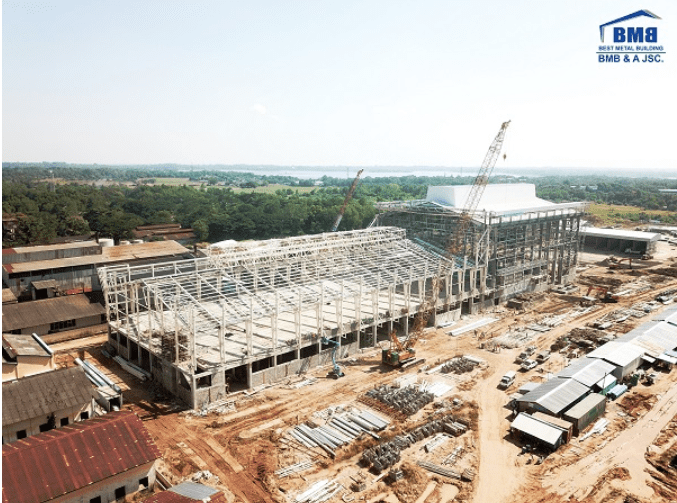

If you’re thinking of getting into the manufacturing business, there are a great number of important things you have to consider before even beginning production. Plant building is a very complex task, and only an experienced builder can do it properly. As a result, your first step should be consulting the building contractor, who will put together a plan for you on how the building will be constructed.

If you are running a manufacturing business and plan to expand, you might have considered expanding outside of your local area like, how much does a manufacturing plant cost, cost to build a manufacturing plant. Expanding your manufacturing plants abroad can be very beneficial for many reasons.

How much does it cost to build a manufacturing plant

Manufacturing facilities are built to handle large volumes of materials, machinery and equipment. They require a lot of space and can typically be expensive to build. The cost of building a manufacturing plant depends on the type of business you’re starting and where you want to build your new facility.

The following factors can affect how much it costs to build a manufacturing plant:

Location. If you’re building in an area that doesn’t have much available land or is remote, you might have to pay more for transportation for raw materials or finished products. This could increase shipping costs, which would be reflected in your overall budget.

Size. The size of your manufacturing plant will directly affect its overall cost because it will determine how much space is needed for production and storage of inventory. If you’re starting a small operation, then using less space will help keep costs down. However, if you’re planning on doing extensive research and development, then having more room may be necessary so that engineers have more room to work with their experiments without having to worry about running into each other as they move around the facility at different times during the day or even weeks while working on various projects at once

The cost of building a new manufacturing plant depends on the size, capacity and complexity of the facility.

Cost to Build a Small Manufacturing Plant

The cost to build a small manufacturing plant can range from $500,000 to $2 million. The larger factor is the location of the factory. If you’re choosing between two different states for your new business venture, you’ll want to consider how much it will cost to relocate employees and materials from one state to another.

Cost to Build a Medium-Sized Manufacturing Plant

A medium sized manufacturing plant could cost anywhere from $3 million to $10 million depending on its capacity and complexity. Medium-sized factories are usually built in industrial parks or industrial areas where there’s plenty of room for expansion as well as access to utilities such as electricity and water. You’ll also want to make sure that every aspect of your operation has access to these utilities so you don’t have any problems during production runs or when it comes time for maintenance work on equipment inside your facility.

Cost to Build a Large Manufacturing Plant

Large manufacturing plants can cost anywhere from $10 million up into the billions depending on how much production capacity they have and what kind of technology they use throughout the entire production process

How much does it cost to build a manufacturing plant?

The answer depends on the size of your company, how much equipment you plan to install and the location of your plant. The average cost for a manufacturing facility is $750 per square foot. This includes both the building and any interior finishing touches such as lighting, flooring and walls. If you’re looking for an existing building that can be used as is, expect to pay around $400 per square foot for renovation costs.

How much does it cost to build a manufacturing plant?

The answer depends on the size of your company, how much equipment you plan to install and the location of your plant. The average cost for a manufacturing facility is $750 per square foot. This includes both the building and any interior finishing touches such as lighting, flooring and walls. If you’re looking for an existing building that can be used as is, expect to pay around $400 per square foot for renovation costs.

A manufacturing plant is a facility where raw materials are transformed into finished goods. A factory is a place where goods are produced on a large scale. The cost of building a manufacturing plant can vary depending on the size of the facility, the type of machinery and equipment used and whether it is outsourced or built by in-house labor.

The cost of building a factory depends on several factors including:

Location: The cost of real estate varies from state to state, country to country and city to city. For example, if you want to build your factory in New York City, you will be paying more than if it were built in Omaha Nebraska.

Size: Bigger factories tend to be more expensive than smaller ones since they require more space and workers to run efficiently. However, this does not mean that small factories are less expensive than big ones; it just means that they have fewer machines and thus fewer employees who need salaries paid out every month.

Equipment: If you want your factory to be fully automated with robots doing all the work, then obviously this will increase costs significantly as compared to having human beings do everything themselves manually (and even then there would be some cost involved).

The cost of building a manufacturing plant depends on the location and size of the factory. A small factory can be built for as little as $1 million while a large plant can cost anywhere from $10 million to $50 million, depending on its size and complexity.

A typical factory has many departments such as design, engineering, production, R&D, quality control, warehouse etc. The construction cost depends on the number of departments in the factory and the space required by each department.

The type of material used also affects the cost. Some materials such as steel are cheaper than concrete or timber while others like granite are more expensive than most other materials. Also, some materials like glass or steel require special care during handling which requires additional manpower and increases costs further.

Cost to build a manufacturing plant

To build a new manufacturing facility, you will need to consider the following factors:

Land and Building Costs

The cost of land and buildings is usually the largest expense in building a new facility. The cost of acquiring land can be as low as $10 per square foot for undeveloped land in rural areas or up to $100 per square foot for land located near major transportation hubs like airports, ports, or interstate highways. The average cost of property acquisition in urban areas is between $20 and $50 per square foot.

Manufacturing facilities typically require between 2 million and 14 million square feet of space, depending on the type of products being manufactured and how they are processed. Manufacturing plants used for processing raw materials into finished goods generally require less space than manufacturing plants that produce finished goods from scratch. For example, a plant that produces steel from iron ore requires more space than one that converts scrap steel into usable material.

The cost of building a manufacturing plant depends on its size and complexity; however, there are some general guidelines:

Smaller plants (2-4 million square feet) typically cost about $40 per square foot for new construction; larger plants (8-10 million square feet)

How much does a manufacturing plant cost?

The cost to build a manufacturing plant varies based on the size of the building, the type of machinery and equipment it will contain and location. A small, single-story building with basic equipment can be built for less than $100 per square foot, while a large facility with high-tech equipment and multiple levels may cost more than $500 per square foot.

The cost to build a manufacturing plant is based on many factors, including:

The size of the building (square footage)

How much automation you want in your facility (robots vs humans)

Where you want to build your facility (prices vary significantly by region)

How much does it cost to build a manufacturing plant?

It’s hard to put an exact figure on what it will cost to build a manufacturing plant, but here are some rough estimates:

Cost per square foot for industrial space is $6.00-$10.00 in the U.S. and $2.00-4.00 in Asia (excluding China).

In the U.S., construction costs are typically 20% higher than in other countries due to higher labor costs and building codes. In addition, land and real estate prices are high compared to most other parts of the world.

The biggest difference between building a plant in China vs. the U.S., however, is that labor is much less expensive in China and construction materials are much cheaper as well (although they may not be of top quality).

The cost to build a manufacturing plant will vary greatly depending on your location and the type of facility you need. A basic food processing plant can cost between $1 million and $10 million, while an auto assembly plant can cost over $100 million.

Factors that affect the price include:

Size: The larger the building, the more expensive it is to build.

Location: Building costs vary by region of the country. For example, a manufacturing plant in California will be more expensive than one in Alabama or Texas because of labor costs and availability of materials.

Utility services: Do you need natural gas, water and sewer service? How much power do you use? Will there be rail access? The answers to these questions will affect how much it costs to build your manufacturing facility.

The cost of building a plant can vary greatly. The size and complexity of the plant will determine how much it costs to build a manufacturing facility.

Construction costs depend on several factors:

The size of the building.

The location of the building.

Whether or not there are existing utilities available at the location.

The type of construction, such as concrete block or steel frame.

The quality of materials used in construction (concrete block versus brick).

How skilled your workers are at building similar types of structures in the past.