Inventory is a database of products that a business keeps in its inventory. It can be used to track the purchasing, production and sales of these items. The database can also store information about each product including its description, cost, tax rate and any other relevant information required for sales or production purposes.

The inventory database should be able to handle all aspects of the business from purchasing through to sales and returns. It will also allow you to track stock levels at different locations and make sure that your business never runs out of stock.

Inventory systems are essential for any business that sells products or services over the Internet. They allow you to enter orders as they come in and keep track of them until they are delivered. If there is an issue with an order then this can be resolved quickly without any loss of time or money on your behalf.

Sample Database For Inventory System

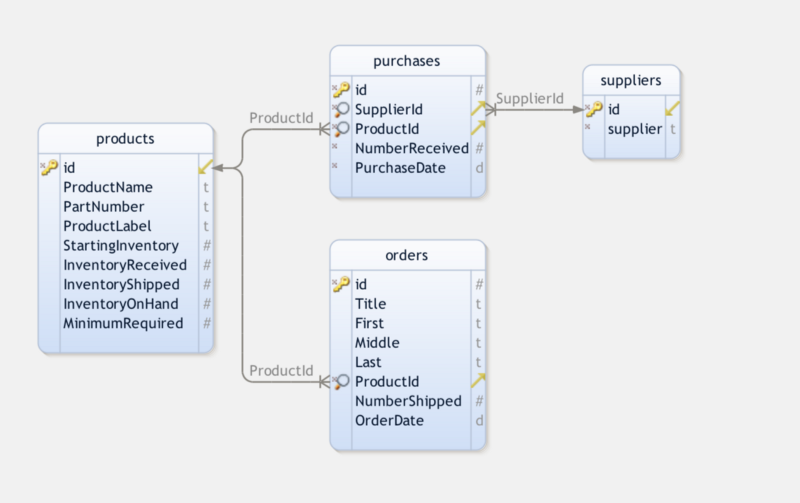

The inventory management system database tables are as follows:

Inventory Item Table: It stores the details about each item in inventory. The fields of this table are Item ID, Item Name, SKU (Stock Keeping Unit), Description, UOM (Unit of Measurement), Price, Quantity On Hand and so on.

Item Line Table: This table is used to store the details about each item line. The fields of this table are Item Line Code, Item ID, SKU (Stock Keeping Unit), Description, UOM (Unit of Measurement) and so on.

Location Table: It stores the details about each location where the items are stored. The fields of this table are Location Code, Location Name, Address1 and so on.

The following tables are used in the inventory management system database.

Table 1: Inventory Transaction Table

Column Name Data Type Description TransactionID bigint primary key AutoNumber(4) Date date/time record was inserted Timestamp(6) OrderNum varchar(100) order number OrderDate date/time order was placed OrderStatus int order status (1=pending, 2=processing, 3=fulfilled) CustomerID varchar(100) customer id ClientID varchar(100) client id ItemNum smallint item number Quantity smallint quantity on hand Description varchar(100) description of item QuantityInStock smallint quantity in stock (units or count) SerialNumber smallint serial number of item (for items with serial numbers) UnitPrice money price per unit CostPrice money total cost of item DiscountPercent float percent discount Rate float rate of discount TaxRate float tax rate TotalPrice float total price PurchaseOrderNum varchar(100) purchase order number BillToAddress varchar(200) billing address ShippingAddress varchar(200

Inventory Management Database

Inventory management systems are used in a variety of industries, including manufacturing, retail and wholesale distribution, transportation and logistics. These databases are designed to help businesses keep track of how much inventory they have on hand at any given time.

The main function of an inventory management database is to keep track of the quantity and location of all products or items within a warehouse or other storage facility. Inventory management software also provides information about when items were purchased, sold and shipped out, as well as who ordered them.

There are many different types of inventory databases available today, but most fall into one of two categories: relational or object-oriented. Relational databases use tables to organize data records into groups based on similar characteristics. Object-oriented databases store data in objects that contain both data fields and methods that perform calculations on those fields. Both types have advantages and disadvantages when it comes to storing inventory management data.

Inventory database design is the most important part of inventory management system. We can use various tools to design an inventory database. The most common tools are Microsoft Access and SQL Server Management Studio.

Inventory Database Table:

1) Item Number: This table contains item number, description, cost, weight and so on.

2) Item Stock: This table contains item stock details like item number, quantity on hand and current stock price.

3) Sales Order: This table contains details of sales order such as customer name, salesperson name, date of order and so on.

4) Sales Header: This table contains details of customer name, salesperson name and date related with sales order.

5) Sales Line: This table contains details about a particular product ordered by customer through sales line such as product code, quantity ordered and unit price etc.

Inventory management is the process of tracking, controlling, and reporting the inventory items that a business owns. The inventory management system database is basically a database which stores all the details related to inventory items. This includes information like product number, name, price and quantity.

Inventory management database has two types:

1) Physical Inventory Database

2) Virtual Inventory Database

Inventory database is a database that stores the inventory records. It is used in the business organizations for managing the inventory data. Inventory database can be created using any database management system such as MySQL, MS SQL Server, Oracle etc. In this post we will discuss how to create an inventory management database in excel using MS Excel database templates.

The following are the inventory database excel templates:

1) Inventory Management System Database Tables

2) Sample Inventory Database SQL Server

3) Best Database for Inventory Management

4) Sales and Inventory Management System Database Design

5) Inventory Database Excel

Inventory Management System Database Tables. In this article, we will learn about the inventory management system database tables in detail. Inventory management is a vital part of any business organization and it is very important to maintain the records of goods and services in an efficient manner.

Inventory Management System Database Tables

An inventory management system database table stores all the necessary information related to your business and helps you to manage your inventory in an efficient manner. There are various ways by which a company can maintain its inventory records. Some of these methods are:

Manual Method: This method helps you to keep track of all the transactions manually. However, it is very time-consuming and requires a lot of efforts from your side.

Computerized Method: This method is used by most companies as it saves their time and efforts by reducing human errors too. It also helps you to keep track of all the transactions easily without any hassle or confusion.

Inventory management system database tables are the central hub of your inventory management system. They store all the data related to your inventory, products and customers. Here is a list of inventory management system database tables:

Part Of Stock (POS) Table

This table stores all the parts of stock and their information such as part number, serial number, unit cost and stock quantity. This table also contains a foreign key column which links this table with other tables like Product Table and Customer Table.

Product Table

This table stores all the product details like product name, description, part number etc. It also contains a foreign key column which links this table with other tables like Part Of Stock Table and Customer Table. This is an important table because it connects multiple tables together forming relationships between them.

Customer Table

This table stores customer details like customer name, email address etc., It also contains a foreign key column which links this table with other tables like Product Table and Part Of Stock Table forming relationships between them.

Inventory Database Design

Inventory management is the process of collecting, analyzing and using information about the products in a company’s inventory. An effective inventory management system helps a company manage its assets more efficiently, reduce waste and loss, improve customer service and increase profitability. It also provides an accurate picture of the organization’s current financial situation.

A successful inventory management system starts with proper planning. The first step is to determine what data elements will be tracked for each item in the inventory. This includes the item number, cost, quantity on hand and location of each item in the facility.

Once you’ve determined what data elements you need to track for each item in your inventory, it’s time to decide which tables will store that data and how it will be related to other tables in your database. You’ll want to create one table for each kind of item that you want to track: raw materials, work-in-process items and finished goods are just some examples of different kinds of items you may have in your inventory.

You’ll also need to decide what information should be stored for each type of item and how it will relate to other items within the same category — such as whether a particular product can be used as an ingredient in another product or if it requires special handling

Inventory database:

Inventory database is the database that is used to store information about products. Inventory database consists of two parts, one is the product information and another one is the stock status. The inventory database is used by all organizations to manage their product related information in an efficient way. It has many advantages over other methods like paper based system or manual system. The most important advantage of this system is that it can be accessed from anywhere at any time and no one has to carry physical files or documents which makes it more efficient than other systems.

Managing inventory in an organization can be done by using different methods but inventory management becomes more efficient when the company uses an inventory management software where they can store all the data related to their products. It also helps them in calculating the amount of raw material required for production and also helps them in calculating the amount of finished goods required for sale so that they can easily manage their stocks efficiently.