A folding sawbuck is one of the more useful pieces of firewood processing gear you can have. A folding sawbuck makes it easy to process firewood. It allows you to easily collect, split and stack your firewood. With a little guide, you can build a folding sawbuck in a few easy steps. The entire project should take no more than an hour or two. Building a folding sawbuck is fun and rewarding.

A sawbuck is a wooden stand for holding logs for bucking (also called splitting) by hand. When the logs are sawed into lengths the sawbuck can be folded up to be more portable until needed again. If you don’t live in the wildwoods and just want to make a rustic looking folding sawbuck that holds wood neatly in your backyard or woodpile, that’s what this article is all about.

How to build a sawbuck

How to build a folding sawbuck. The folding sawbuck is a great project for anyone who wants to cut firewood. It can be built from scrap wood and it folds up for easy storage.

The first step in building this project is to get some scrap wood. You’ll need about 2x4s, some 2x6s, and some plywood or OSB. You can use any combination of these materials (and other materials) that you want as long as they are straight and strong enough to hold up the weight of your log when it’s being cut in half. I used mostly 2x4s and 2x6s with some plywood scraps thrown in for extra strength where needed (like where two pieces met).

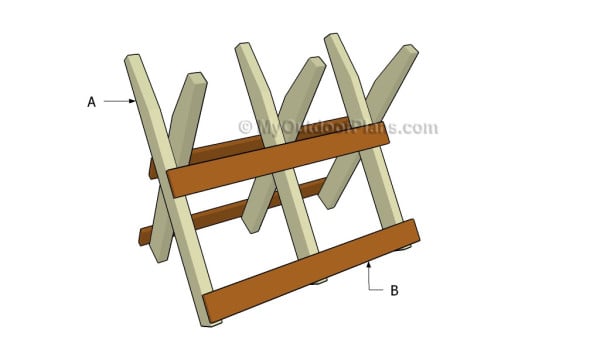

Cut out all your pieces according to the diagram above. You’ll notice that there are two different layouts: one has a gap between two boards while the other one doesn’t have a gap between them. If you’re using a circular saw with a guide then you can use either one but if you’re using a jigsaw or hand-saw then you’ll want to use the layout without gaps because those tools don’t like cutting on an angle or into corners where there isn’t enough room for their blade or teeth

Building a sawbuck is a great project for the weekend. It’s easy to build, and it will help you cut firewood into more manageable lengths.

How to Build a Folding Sawbuck

Step 1: Cut the lumber. The frame of this sawbuck is made from 2-by-4s, while the legs are made from 1-by-4s. Cut all the pieces according to the dimensions in the diagram above.

Step 2: Assemble the base frame. Lay out the four legs on your work surface and attach them together using 3-inch deck screws driven through pilot holes drilled at an angle into each joint (see photo). Make sure that all four sides are perfectly square before driving in any screws.

Step 3: Attach the legs to the base frame by driving screws through pilot holes into each joint (see photo). Make sure that all four sides are perfectly square before driving in any screws.

A sawbuck is a portable workbench that you can use to cut large pieces of wood. It’s also called a trestle or “saw horse” because it works like a horse, holding up the wood for you to cut. You can build one in about an hour using only two pieces of wood and a few nails.

Step 1: Cut two lengths of 2×4 lumber: 24 inches long and 12 inches long.

Step 2: Nail one long 2×4 piece across the shorter piece at a 90-degree angle so that the top of the long board is flush with the bottom of both short boards (see image). The legs should be 10 inches apart. If your legs don’t line up perfectly, make sure that the top edges are flush with each other and screw them together using three screws each leg for extra strength.

Step 3: Flip over your new sawbuck so that its legs are facing down and attach another short 2×4 on top by nailing it into place (make sure it’s lined up with your original sawbuck legs). This will become your working surface once you flip it back over onto its feet.

A sawbuck is a simple device that can be used to stack and store firewood, or other long items. If you want to build your own sawbuck, here’s how:

Build the frame. The frame of a sawbuck is made from 2x4s, as this will give you enough strength without adding too much weight. Cut two pieces of 2×4 to length at 6 feet each (1.8 m). You’ll also need two more pieces at 2 feet each (0.6 m).

Use two 8-inch long lag screws to secure these four pieces together into a rectangle shape with the longest side facing up.

Assemble the legs. Cut four pieces of 1×4 lumber at 16 inches long each (40 cm). Attach one end of each leg onto the top of your rectangle by drilling pilot holes for your screws before driving them in with a drill/driver and screwdriver attachment on an electric drill. Place one leg directly over the other so that the shorter ends are flush with each other and use two more 8-inch lag screws per leg to secure it in place (you’ll need an extra set if you don’t have an electric drill).

A sawbuck is a simple way to make firewood easier to split. It’s basically two pieces of wood connected by an angled brace, with notches cut out of the top and bottom pieces so that when logs are placed on top of the sawbuck, they can be split along the grain more easily.

Here’s how to build your own:

Cut two pieces of 1″ x 8″ lumber about 4′ long (if you’re taller than 5’4″, use 2x4s instead). The height should be about as tall as you are. Cut another piece of 1″ x 8″ lumber about 2′ long. This will be used for the brace that connects the two main boards together.

Mark two lines on each board that are 2-3″ apart from each other at both ends, then drill holes in those marks so you can nail through them using nails or screws. These holes should be just above where you plan on making notches in step 3 (see above photo).

Now measure down from those drilled holes and mark spots where you want notches cut out (see below photo). Use a hand saw or jigsaw to cut these notches out; it doesn’t need to be perfect because we

How to Build a Firewood Sawbuck

Sawbucks are an essential tool for any serious firewood cutter. They make it easy to stack split firewood in rows so that you can get at it easily and quickly. They also make it easy to cut firewood into more manageable lengths, which makes it easier to move around and store. If you have an old sawbuck lying around in the garage or shed, you might want to upgrade it with these plans for a folding sawbuck that can be stashed away when not in use.

Materials list:

4×4 post – 4 feet long

2x4s – 2 feet long

A sawbuck is a simple, portable and very effective tool for cutting firewood. It is simply two wooden boards with a notched joint that allows them to fold together and stand upright, forming a ‘V’ shape that can be used to hold logs for cutting.

As you can see, it’s very easy to build one. The only materials you need are a couple of 1×4 pieces of lumber (3/4″ thick), some plywood or other material for the bottom, and some screws or nails. I recommend using screws whenever possible as they are much less likely to come loose over time.

1) Cut your 1x4s into five equal lengths – each should be about 14 inches long (35 cm). Make sure you don’t cut them too short! You’ll need room for the notches and the plywood board below them at the bottom.

2) Cut the plywood into two pieces that are 14 inches long by 8 inches wide (35 cm x 20 cm). These will form the sides of your sawbuck.

3) Lay down one piece of 1×4 on top of another at right angles so that they overlap by about an inch (3cm). Mark out where your joint should go using a pencil

A folding sawbuck is a great way to stack wood for splitting. It’s very simple to build, and much easier to use than trying to split by hand.

The first thing you’ll need is some lumber. You can use anything from 2x4s to 2x12s as long as it’s straight and strong enough to hold up the weight of your woodpile. The length of each piece will be determined by the size of your woodpile, but it should be at least twice as long as the woodpile itself so that when you’re done you have something sturdy enough to support itself without falling over.

When choosing lumber for this project, avoid using dimensional lumber (ie: 2x4s) or any type of softwood like pine or fir because they tend to warp over time when exposed to moisture and humidity. Hardwoods like oak or maple are good choices because they’re more durable and have less chance of warping over time. The best option would be using treated lumber since it will last longer than untreated lumber, but if you don’t have access to treated lumber then go with hardwoods instead because they’re at least better than softwoods!

You’ll also need some nails or screws (preferably stainless steel) and

This is a simple but effective way to make a portable sawbuck for cutting firewood. It’s easy to build and can be quickly taken apart and stowed away when not in use.

A sawbuck is a frame used to hold logs in place while they’re being cut by hand saws. It’s a simple device that can be made from just about anything, but most people use scrap lumber or metal pipe fittings to create them.

The ones I’ve seen are very heavy and bulky, which makes them difficult to store when not in use. They also tend to get damaged over time because they’re made with nails or screws instead of glue.

This version is lightweight and easy to store away when not needed. It’s also inexpensive since you don’t need any special tools or materials other than what you probably already have at home:

Two 2x4s – used as legs (the length depends on how tall you want it)

One 2×8 – used as side rails (the length depends on how wide you want it)

Four 4x4s – used for braces between legs and rails (length depends on desired width)

A sawbuck is a simple frame that holds logs steady while you cut them. The basic design consists of two sawhorses with a cross-piece between them. You can adjust the height of the cross-piece, which makes it easier to chop at an angle or turn logs over to work on their ends.

A sawbuck is fairly easy to build and can be an indispensable tool. This article will show you how to construct one in just a few hours.

You’ll need four 6′ 2x4s and eight 1/2″ x 4″ carriage bolts with nuts and washers (or hex head lag screws), as well as some wood glue and paint or stain if desired. You might also want some sandpaper for smoothing out rough edges after assembly.