You want to build a jet engine, right? So do I. Only this is not what you are used to. This is not some “how to build a jet engine” full of theoretical calculations, detailed drawings and arcane materials science. This is something else entirely.

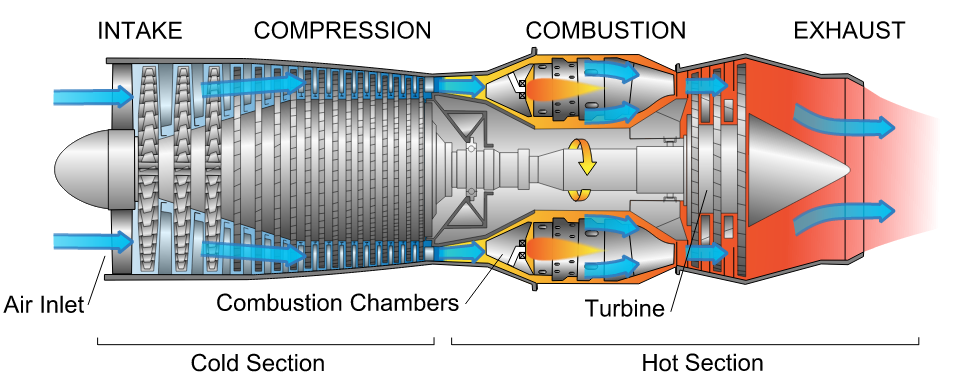

When thinking about how a jet engine works, it’s tempting to think of the engine as two separate parts: the compressor and the combustion chamber or, for us laymen, the fan and the burner. In actuality, however, a jet engine is really one continuous process, where air is sucked into the front of the engine, compressed by a series of fans and rotors, mixed with fuel in the combustion chamber, and expelled out the nozzle at high speed.

How to build a jet engine

To build a jet engine, you need to fabricate the parts from steel or aluminum and then assemble them. You also need to test your engine and make sure it works properly before installing it in your plane.

The most difficult part of building a jet engine is fabricating all the parts. You can use standard tools such as saws, drills and lathes to make these parts, but you’ll need special equipment for some of them. For example, a plasma cutter makes it easy to cut through thick metal quickly and efficiently. A laser cutter can also help you cut intricate shapes into thin sheets of metal — if you’re working with thin sheets of material like paper or plastic, you can use an X-Acto knife or utility knife instead.

Some of the parts that are most important for your jet engine include:

Air intake — The air intake provides air for combustion inside the engine and forces air out through exhaust ports at the back of the engine. This allows thrust to be generated by forcing hot gases out through these ports while drawing in cool new air through another set of ports on top of the engine called “inlet ports.”

Compressor — The compressor compresses air so that it becomes more dense and more powerful when it enters into the combustion chamber where

Jet engines are the most powerful type of aircraft engines. They power both civilian and military aircraft, and are commonly found on commercial airliners, fighter planes, helicopters and other types of military aircraft.

Jet engines work by sucking in air and compressing it to high pressure before mixing it with fuel and igniting it to produce thrust. The energy released by this process propels the plane forward.

The earliest jet engine was invented by Sir Frank Whittle in 1930. It used a centrifugal compressor rather than a turbine, which made it simpler but less efficient. The first operational jet plane was the Messerschmitt Me 262, which flew for the first time in July 1942. The first commercial jet plane was the British Comet 1A (registered G-ACSS), which first flew on 4th June 1952 from London Heathrow Airport to Johannesburg South Africa via Rome, Naples, Beirut and Khartoum Sudan where it stopped for refuelling before continuing to Jan Smuts International Airport at Lanseria Johannesburg South Africa with Captain James McBryde at the controls having taken off from London Heathrow Airport at 05:20hrs GMT on Monday 4th June 1952 arriving back at London Heathrow Airport at 07:00hrs GMT on Tuesday 5th

The jet engine is a type of internal combustion engine that uses a ducted fan to direct highly compressed, accelerated air rearward in order to generate thrust. The mechanical layout of a typical turbofan engine is shown in the figure below.

The main parts of a turbofan engine are:

Compressor — This component compresses ambient air and feeds it into the combustion chamber.

Combustion chamber — A device containing fuel and air, where combustion occurs. The combustion products then enter the turbines and exit as thrust.

Turbine — This component takes the exhaust gases from the combustion chamber and uses them to generate power for propelling the aircraft.

Jet engines are among the most complex machines on Earth, but they’re also some of the most powerful.

A jet engine works by sucking in air, compressing it and then forcing it out through a nozzle at high speed. The engine extracts energy from this fast-moving air, which is then converted into thrust that propels the aircraft forward.

There are two main types: turbojets and turbofans. Turbojets use a turbine to compress air, while turbofans have a fan that helps turn the compressor.

Turbofan

Turbofans are more efficient than turbojets because they get more thrust from each kilogram of fuel burned. They also produce less noise because they have multiple streams of air going into their compressors instead of just one stream like a turbojet does.

The engine is designed to rotate, so it must be mounted on a swivel. The engine may be attached to the swivel by means of a pin, or it may be bolted directly to a mounting block attached to the swivel.

The compressor section is made up of many fan blades and smaller compressor blades. These are called “blisks” because they look like blimps. They are actually shaped like the blades of an airplane propeller. The fans draw air into the engine through an inlet duct, which is located on top of the wing. Compressor blades create more pressure in order to compress air and increase its temperature before it enters the combustion chamber.

The combustor section contains fuel injectors and igniters that supply fuel and oxygen to the combustion chamber where they react with each other and produce heat energy that drives turbines turning shafts connected to compressor blades, giving them power for their work in compressing air for burning fuel in later sections of engine.

The turbines section contains turbine shafts which turn due to hot gases produced by burning fuel passing through combustor section above turbine blades causing them to spin like water wheels when passing through water channels behind turbine blade rows causing them