A free-standing lean-to shed might be exactly what you need for your outdoor storage needs. A free standing lean-to shed is perfect for those who don’t have a lot of space, but still need more than just a tool shed.

If you can’t afford to build a full shed, then perhaps a lean to is a better solution. If you don’t have the required amount of direct sunlight, it will still help protect your items from the elements but allow light to come in how to build a lean to how to build a lean to on side of house how to build a lean to off a garage and . It’s not as spacious as a box shaped storage shed but will do the job just as well if you need it.

how to build a free standing lean to

Lean-tos are a great way to add extra living space to your home. They can be built in a variety of shapes, sizes and locations. The most common lean-to is attached to the side of the house and made from plywood or OSB boards. You can also build it off the back of a garage.

The following instructions are for building a free-standing lean-to with a gable roof. The size will depend on how much room you have available, but the basic principles remain the same regardless of size.

How to Build a Lean-to

A lean-to is a roofed structure that’s built onto the side of a house, garage or other building. It can be used for storage, as a workshop or even as an extra space for a bedroom or bathroom.

Lean-tos are easy to build; you just need some basic building skills and tools. If you’re looking for more information on how to build one, read on!

How to Build a Lean-to: Materials You’ll Need

The materials needed for this type of project depend largely on what kind of lean-to you’re planning to build. Here are some general guidelines:

Sturdy lumber — This is usually 2x4s (two inches by four inches) or 2x6s (two inches by six inches). You’ll need at least one 6×12 piece of plywood for the roof. The more lumber you have, the sturdier your finished product will be.

Nails — Use galvanized nails that are at least 1¼ inch long with square heads that can hold up under pressure without pulling out easily.

Screws — Screws work well too; they’re just not as strong as nails alone when it comes time

A lean-to is a simple, open-sided structure that can be built against the side of your house or directly onto the ground. This type of structure is also called an open-fronted shed.

Build your lean-to with 2×4 lumber (or other full dimension lumber). The length of each 2×4 will depend on how far out from the wall you want your roof to extend. A typical 12 foot wide lean-to will require about 50 feet of 2x4s for the frame and another 30 feet for the roofing material.

If you have access to a sawmill, you can build a much sturdier structure from full dimension lumber. Use 2x6s for all framing members if possible as these are stronger than 2x4s. You’ll need about 20 less framing members than for a framed structure but it may be worth it if you plan on using it as storage or workshops space.

Lean-to structures are one of the easiest to build. They’re also very functional and can be built in a variety of ways.

A lean-to is basically a shed attached to the side of your house. It can be used for storing tools, lawn mowers, gardening supplies and more. It’s also great for adding a covered area to an existing deck or patio.

There are many different ways to build a lean-to structure, but here we’ll show you how to build one with a gable roof that’s attached to your house. This type of lean-to is also called a “shed dormer” because it looks like an extension of your house with windows on both sides and a door in the middle.

A lean-to is a simple structure that can be built by almost anyone with basic carpentry skills. It’s a perfect way to add shade and storage space to your yard or garden, and it can be constructed in a weekend. This project is also an affordable alternative to building a permanent structure.

1. Select the location for your lean-to. Choose an area close enough to your house so you can easily transport materials from the garage, but far enough away that it won’t shade your home’s windows. The lean-to should be situated on level ground with good drainage so it doesn’t rot prematurely. If you plan to put an entrance door in the side wall, consider adding an eave overhang to protect it from rainwater that may run off the roof.

2. Make sure the chosen site receives at least six hours of direct sunlight per day so plants will thrive inside the structure. Also make sure there are no overhead power lines or other obstructions above or within 10 feet of the lean-to’s footprint.

3. If you’re building a free-standing structure, use treated lumber (2x4s) for framing members instead of plywood sheets because they’re

how to build a lean to off a garage

How to build a lean-to off a garage. This is an easy, inexpensive way to add some extra space to your garage. You can use this design for any size of garage and you don’t have to be an expert carpenter either.

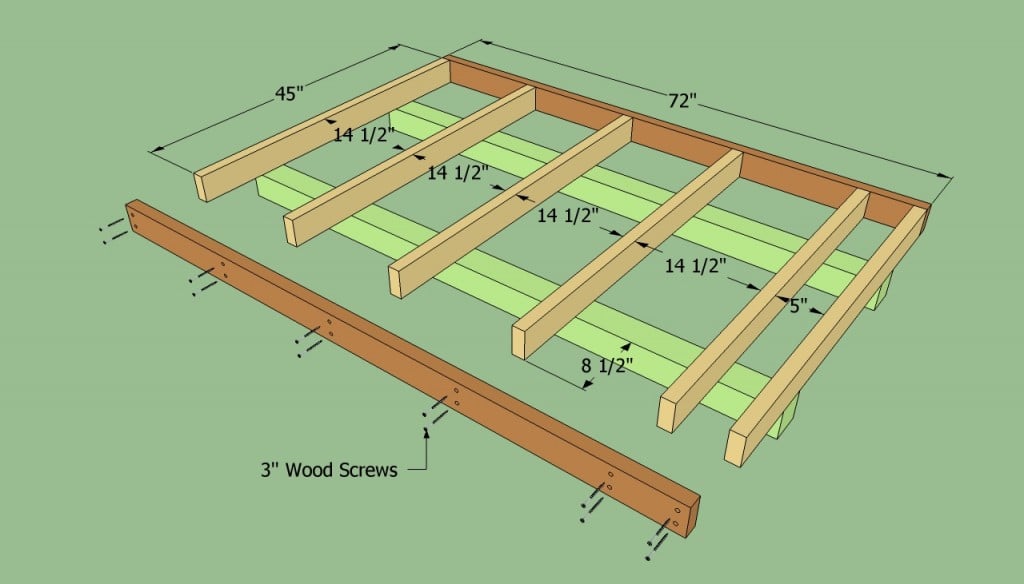

The first thing you need to do is get your materials together. The dimensions in this article are based on a 24′ x 36′ garage with an 8′ high roof (4′ overhang). The materials list includes:

2 – 4x4s = 36″ long (for headers)

2 – 2x6s = 72″ long (roof joists)

3 – 2x4s = 48″ long (rafters)

1/4 inch plywood for the roof decking

8 foot wide sheets of 3/4 inch plywood for the walls and ceiling

2x2s for trim pieces around doors and windows

A lean-to is a type of structure that is typically built on the side of a house or garage. It can be used to add extra space, such as a storage room, an office or even a bathroom. The lean-to is made out of wood and can be constructed in the same way as any other type of building.

The first step in constructing a lean-to is to build the foundation. Pour concrete into the ground where you want to place your lean-to. The foundation should be about 4 inches thick and allow for drainage if it rains often in your area.

After pouring your concrete, set up your posts for supporting the structure. These should be placed about 2 inches apart from one another and should be straight up and down once they are in place. Make sure that you have enough space between posts so that they don’t interfere with each other when it comes time for attaching them together with braces or cross beams.

After setting up your posts, attach them together with braces or cross beams running across each one at different heights so that they form an X shape while being supported by posts on either side of them at each point where they cross over one another. This will help stabilize