At first glance, the idea of building a 3D printed house seems ludicrous. How is printing a house practical? A typical home can take over a month to print and cost over $150,000. (Metals) Can we really print a home for less than the price of an apartment?

There are two ways to get an end-to-end 3D printed house. One is to build your own. The other is to outsource it to a company that specializes in 3D printers to build it for you. That’s exactly what Icon and IconPLUS are here for. Together they can help you design, plan, and manufacture a custom-sized home or commercial structure that fits your needs and matches your budget.

How to build a 3d printed house

3D printing is already used to print small parts and prototypes, but it’s still too expensive to print full-size houses. But as the technology advances, it will become more affordable and practical.

3D printing house material:

The materials used for 3D printing are not yet ideal for building houses. The most common material is plastic, but it’s not strong enough to support a roof. Other materials could be used, such as sand or concrete mixed with steel fibers.

3D printed house company:

There are several companies working on 3D printed homes, including Icon, which has built a prototype called Vulcan that can be assembled in just 24 hours from pre-fabricated parts (see video below).

3D printing has been used to create everything from prosthetics to food, but now the technology is poised to move into the construction industry.

Building a house with a 3D printer could soon be as easy as printing a document on your home computer. It may sound like science fiction, but it’s already happening in China and other parts of the world.

Here’s everything you need to know about 3D printed houses.

There are several companies working on printing homes right now. Icon, a Chinese company founded by two architects, has already built two prototype houses using its proprietary system. The company plans to start building more on a larger scale in 2020.

In December 2018, the first American-made 3D-printed house was completed in Austin, Texas. Built by ICON with help from New Story and Colorado State University, this project marks an important milestone for 3D-printed housing in America.

3D printed houses and homes have been around for a while now. But they’re still pretty rare. And when you do see them on the market, they can be quite expensive.

This article will tell you everything you need to know about 3D printed houses and homes, including how much they cost, who’s building them, how they’re made, and more.

3D printing has been around for decades now, but it hasn’t yet made its way into the home-building market in any significant way — at least not yet.

There are two main reasons for this: The first is that building codes across the world vary widely from country to country and state to state, so it can be difficult for builders to know what regulations they must follow when using new technologies like 3D printing. In some cases, it’s easier for builders to stick with traditional methods such as concrete or wooden framing instead of trying something new that might require additional approvals from local or national governments.

The second reason why there aren’t many 3D printed houses yet is that most people don’t want them anyway! In fact, many buyers choose their homes based on how traditional

3d printed houses are the future of housing. They’re faster and cheaper to build, and can be used in any location.

The first 3D printed house was built in Russia in 2016, but it wasn’t until 2018 that a company called Icon unveiled plans for a $10 million factory in Texas that will produce 500 homes a year by 2020.

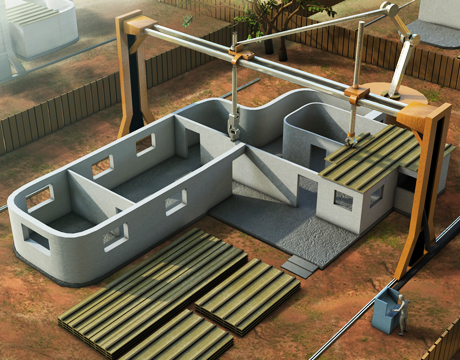

3D printing is an additive manufacturing process that can create objects with 100% of the material needed to make them. The process involves depositing layers of materials and is often compared to how children create buildings out of Lego bricks.

Materials used include concrete, steel and plastics. For example, Icon is using steel-reinforced concrete which they claim has better insulation than wood or brick buildings.

3D printed houses are on their way.

The first one was built in China in 2016, and they’ve been popping up all over the place since then.

But what exactly do 3D printed houses look like? How much do they cost? And when can we expect them to be available for purchase?

Here’s everything you need to know about these new homes:

While there are many different types of materials used for 3D printing homes, the most common material is concrete. The process involves layering concrete with a machine that sprays it out in layers as needed. Each layer is only a few millimeters thick, but it adds up quickly to make a solid foundation for your home.

Some companies are experimenting with other types of materials, like plastic or fiberglass reinforced gypsum (FRG). These materials have some distinct advantages over concrete — namely, they’re lighter and easier to move around once they’re built. But they also tend to be more expensive than traditional concrete foundations.

3D printers have been around for a while now, but they’ve only recently become affordable and easy enough that most people can use them at home. As you might imagine, there are all sorts of things you can print with these machines.

In fact, there are even some people who have used 3D printers to build their own houses. These aren’t just small structures either — some 3D printed houses include multiple stories and even full amenities like plumbing and electricity.

When Will 3D Printed Houses Be Available

The first printed house was built by D-Shape in 2009, but it took them several years to make the technology work properly. The company has since built several additional homes using the same technique, and they’re now working on a new one called “New Story” that will be available for purchase soon.

Another organization called Apis Cor is also building affordable 3D printed homes using concrete molds instead of sand molds like D-Shape does.. Their goal is to create an affordable housing solution for people living in areas where traditional construction is too expensive or impractical (like deserts).

3d Printed House Material

Currently, most 3D printed houses are made out of concrete because it’s cheap and strong enough to support its own weight

The question of when 3D printed houses will be available has been asked many times, but the answer is that it’s not yet here. In fact, it may still be several years away. There are many factors that need to come together before we see a home built using this technology on a large scale.

3D printing is an additive process, which means that it builds things up, layer by layer, until the object is complete. The layers are typically made out of plastic or cement and they can range in thickness from 0.1mm to 10mm depending on the printer used. When printing a house you need something that can withstand weather, fire and impact – all of which makes finding the right material difficult to find.

However, there are several companies working on this problem including Icon and D-Shape who have already built some impressive prototypes with their own unique designs for 3D printed homes.

3D printing is the future of construction. That much we know, but the question of when we’ll have 3D printed houses available has been up in the air. Now, a company has answered that question with a release date of 2020.

Icon, a construction firm based in Singapore, plans to provide people with homes made out of concrete and sand by 2020. The company says it will be able to produce a house in just 24 hours using 3D printing technology and will cost $10,000 — less than half of what most homeowners pay for homes built by conventional methods today.

The biggest advantage of these homes is that they’re made from materials found on Earth and are sustainable. Icon says its materials can withstand even the strongest earthquakes and typhoons. And because Icon can control every aspect of its construction process, it can ensure that each home is structurally sound and energy efficient before it’s delivered to its owner.

3D printing is the future of construction. While it may not have taken over just yet, it has made a big impact on the industry in the last few years. It’s only a matter of time before 3D printed houses become as common as traditional construction.

In this article, we’ll explain what 3D printed houses are, how they’re made and when you can expect to see them available for purchase.

What is 3D Printing

3D printing is a manufacturing process that uses layers of material to create items from scratch. It’s also referred to as additive manufacturing since each layer adds more material until an object is completed.

The first 3D printers were created in the 1980s using stereolithography (SLA) or selective laser sintering (SLS). Both processes require expensive materials and precise computer controls to print objects accurately. Since then, cheaper methods have emerged that allow home users to print items on their own desktop machines

Today there are many different types of 3D printing technology including direct metal laser sintering (DMLS), fused deposition modeling (FDM), stereolithography (SLA) and selective laser sintering (SLS). Each has its own advantages and disadvantages depending on what material you want

3D printed homes are still in their infancy, but they’re likely to become more popular over time.

The idea of printing a house is nothing new. In fact, it’s been around since the 1980s. But until recently, it was only used for small parts and prototypes that could be made using existing technology. However, 3D printing is now evolving into an affordable way to build entire houses in a matter of days or weeks rather than months or years. And these houses are not just built from raw materials — they can also be customized for each individual family’s needs.

The first 3D printed house was built by D-Shape in 2010 in Italy. The company has since built another home in France and is working on plans to print a series of houses on top of each other to create multi-story buildings.