As a DIYer, one of your aspirations to build things yourself. But the thing is that research on what would be the best for your application requires you to explore freely, and at times it can get expensive (if you are spending money). For example, without knowing what exactly you want or needing, you might end up buying an unsuitable gasifier.

The concept for this project is extremely simple. Start with clean air and end with anything that you want to burn. Currently, the gasifier produces charcoal and cooking gas (aka, propane). This was accomplished by burning the wood on both ends of the temperature scale (charcoal at lower temperatures and liquified wood products at higher temperatures). tiny wood gasifieR wood gasifier generator for sale But in theory, it’s possible to produce a variety of different gasses by modulating the temperature.

How to build a gasifier

A wood gasifier is a device that converts woody biomass into syngas, a mixture of carbon monoxide and hydrogen. Syngas can be burned directly in internal combustion engines or used as a fuel source for generating electricity in gas turbines. Since syngas contains only up to 70% of the energy of the original wood, it must be enriched before it can be used as a fuel.[1]

Gasifiers exist in many different designs and sizes. They range from small devices made from steel cans and piping to large industrial machines costing hundreds of thousands of dollars[2]. The smallest devices are often called “tinies” or “tiny wood gasifiers”. The most common design for a tiny wood gasifier is the one described by Jim Riley[3] and later modified by Tom Murry[4].

Tiny Wood Gasifier

The tiny wood gasifier is a simple, low cost and easy to build gasifier. It is ideal for laboratory work or as a first step into making your own gasifier. The design has been published in the book “Build Your Own Gasifier” by Christopher M. Jones and can be downloaded here.

The design uses a 2 inch diameter pipe for the main body of the unit. This makes it relatively small and portable but also limits the amount of wood that can be processed at any one time.

The tiny wood gasifier has a capacity of around 1 cubic meter per hour which makes it suitable for hobbyists who want to experiment with gasification on a small scale.

It has been designed so that it can be built from common materials such as steel pipe or galvanized steel sheet metal. There are no specialist tools required for assembly other than basic hand tools such as pliers and wrenches.

Wood gasifiers are a great way to convert wood chips into gas. They can be built in the backyard, or purchased ready-made.

The first step is to decide what size unit you want: you can build a tiny wood gasifier that can run an engine or other small device, or you can make a larger unit that supplies a home with energy.

If you want to build your own, there are many designs available online — this one is just one example. The basic principle is the same: fuel (wood) is burned in an enclosed space, which creates a hot gas (CO). This gas goes through a heat exchanger and creates steam that drives an engine or turbine.

You will need some tools and materials:

– Sheet metal

– Welding equipment

– A pressure cooker

– Some pipe fittings

Wood gasifiers are fairly simple devices, and they can be built with a variety of materials. Most wood gasifiers share some basic features:

The firebox is where the fire burns to heat up the gasifier. The firebox is surrounded by a heat exchanger that transfers heat from the hot exhaust gases in the flue to the incoming air. This ensures that there is enough oxygen to keep the fire burning. In some designs, the firebox and heat exchanger are combined into one piece (like a stove pipe).

The ash box is where ash and other solid material accumulates. If you’re using a small unit like I did, an ash box isn’t really necessary — just dump it out when you’re done using it (note: this will ruin your grass). If you use a larger unit, you may want to consider adding an ash box to collect ashes which can then be disposed of easily without dumping them on your lawn or driveway.

The gasifier is where everything happens! This part of your unit will be made from either ceramic beads or perforated metal tubes called “trays.”

Wood gasification is a process that changes wood or other biomass into synthesis gas, or syngas. Syngas can be burned for heat or converted to electricity in a gas turbine or a steam engine. This process is called gasification because the solid fuel is not burned directly, but instead undergoes reactions with gases from the air to yield CO and H2.

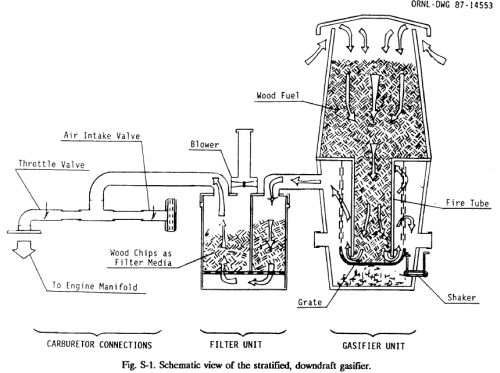

Wood gasifiers can be simple and cheap, or rather complex and expensive. A typical device consists of a combustion chamber, in which the wood is burned, and an expansion chamber that increases its pressure before it enters another combustion chamber where it burns once again. The hot exhaust gases then go through a heat exchanger, which heats up water that is then used to drive a turbine-generator set (or other prime mover) to produce electricity.