When you’re considering building a lean to shed, it’s important to understand the costs associated with the project. While there are many factors that go into the cost of your lean-to shed, there are some basic principles that will help to keep your costs down.

The first step is to determine what type of materials you want to use for your lean-to shed. There are many different options available including wood, metal and vinyl. Each material has its own advantages and disadvantages but which one is right for you depends on how much money you want to spend as well as how long you want the structure to last.

When choosing a material, consider how long you plan on staying in the same location as well as whether or not you plan on ever moving again. If so, then it might be best if you choose a material that will last indefinitely such as metal or vinyl rather than wood.

Another factor to consider when choosing a material is how much time it takes for someone who is skilled at construction work to build an average sized lean-to shed using that particular material. For example, if it takes someone eight hours per day for five days straight just to build an average sized lean-to shed out of wood then it makes sense

Cost to build lean to shed

I would like to build a lean-to shed on the side of my house. I don’t want it to look like an afterthought, so I want to make it look like it was designed that way from the beginning.

I’m thinking of making it about 4 feet wide and 8 feet long. It would be about 3 feet off the ground and 5 feet tall.

The roof would be shingled with asphalt shingles. The floor would be plywood with a layer of insulation underneath. The walls would be rough sawn lumber (8X8s) and the door would be made from 1X6s. I’d like to put some sort of ventilation in there as well, but I’m not sure exactly how to do that yet.

How much should this cost? Do I need a permit? How hard will it be to build? Is building your own shed cheaper than purchasing one?

Building your own shed is a rewarding experience. Not only will it save you money and time, but it also gives you a sense of accomplishment.

There are many factors to consider when building a shed, including size, type and location. If you’re building a lean-to shed, for example, make sure there is enough space for it to extend at least 5 feet beyond the side of your house or garage.

You may need to get a permit if your shed exceeds certain roof height requirements or if it’s attached to another structure. However, most municipalities allow homeowners to build sheds without permits if they meet certain criteria.

The average cost of building a 4×8 lean-to shed with standard materials is around $1,000-$2,000 depending on the size and features. Prices can vary depending on what type of material you choose (wood versus vinyl) and whether or not you hire a contractor or do it yourself

The cost to build a lean-to shed depends on the size of your shed and what you want to do with it. Sheds can range in size from small 4×6 sheds to large 8×12 sheds, and they can be used for a variety of purposes.

If you’re looking for a small shed to store lawn tools or garden equipment, then you probably only need a 4×8 lean-to shed. These small storage sheds are less expensive than larger ones because they don’t require as much material or labor.

If you’re looking for an affordable way to add extra living space to your home, then a larger 8×12 lean-to shed may be the answer. This type of building is still less expensive than adding onto your existing house, but it will cost more than buying an inexpensive storage shed.

A lean-to shed is basically just an extension of your house that gives you more room without having to make any major additions or changes to the original structure. They are usually attached on one side where there is already an existing wall, so this helps keep costs down even further than a regular storage shed would.

A lean to shed is a great addition to your yard if you want a small space for storage or gardening. You can build one yourself with basic carpentry skills.

Costs

The cost of building a lean to shed will depend on the size and materials used. A 4×8 lean to shed is a common size and typically costs between $1,000 and $2,000 to build using standard materials. The average cost per square foot is between $20-$30, depending on the site preparation and foundation work required.

Materials Required

The materials that you need to build your lean to shed will depend on the size of the structure and whether you are building it yourself or hiring someone else to do it for you. Here are some of the materials that may be required:

Wooden posts – These support the framework of your lean-to shed and are usually made from fir or cedar wood as they are strong and durable enough for constant exposure to moisture in most climates. You can also use treated lumber for long-term durability if your climate doesn’t get too cold but has plenty of rain during winter months. Posts should be spaced about 4 feet apart at each end, with one post in each corner of

Building your own shed can be an affordable alternative to buying a pre-built one. You can save money by buying materials in bulk and building it yourself.

The cost to build a lean-to shed varies depending on the size of the shed and the materials you choose. The average cost of a small shed is $2,000, according to HomeAdvisor.com.

How build lean to shed

The cost to build a 4×8 lean to shed depends on the materials you purchase and the complexity of your project.

A simple lean-to shed can be built for about $500, while a more complicated shed with an attached garage might cost $1,500 or more.

Choose DIY Materials

The easiest way to save money is to go with DIY materials. You’ll find that buying lumber and other supplies yourself will often be cheaper than paying someone else to do it for you.

Look for Discounted Materials

Once you’ve chosen your materials, look around online or at local hardware stores for discounted items. Some large hardware stores offer discounted items on Fridays and Saturdays, while others offer discounts throughout the week as well. You can also check Craigslist or buy used materials from friends and neighbors who are remodeling their homes.

Recycle Old Lumber

Don’t throw away old 2x4s or plywood scraps — recycle them by using them for your shed project! Old 2x4s can be cut into pieces that fit perfectly into corners of your new shed frame without cutting or sawing at all! And if your new

Building a lean to shed is a great way to expand your home’s storage space without taking up valuable square footage. A lean to shed can be attached to the side of your house or garage and it does not require a permit from the city or county.

Materials needed:

4×8 plywood sheeting (for the roof)

12′ 2x4s (for framing)

1″ x 4″ wood strips, cut in half lengthwise (for siding)

1/2″ plywood sheeting (for floor)

Wood screws

Nails

The cost to build a shed varies greatly depending on the size and the style of the shed. If you are building a shed to store things, then you will need to consider how much storage space you need. You will also need to decide whether or not you want a roof over your shed. This will add between $200 and $1,000 to your budget depending on the type of material used for the roofing.

If you are looking for cheap storage options that don’t require any permits or inspections, then there are many options available online. You can find kits that come with all of the materials needed to build your own shed at home without having to hire someone to do it for you!

If you want something more professional looking, then it is best to hire a contractor who can provide an estimate based on what kind of shed design you have in mind.

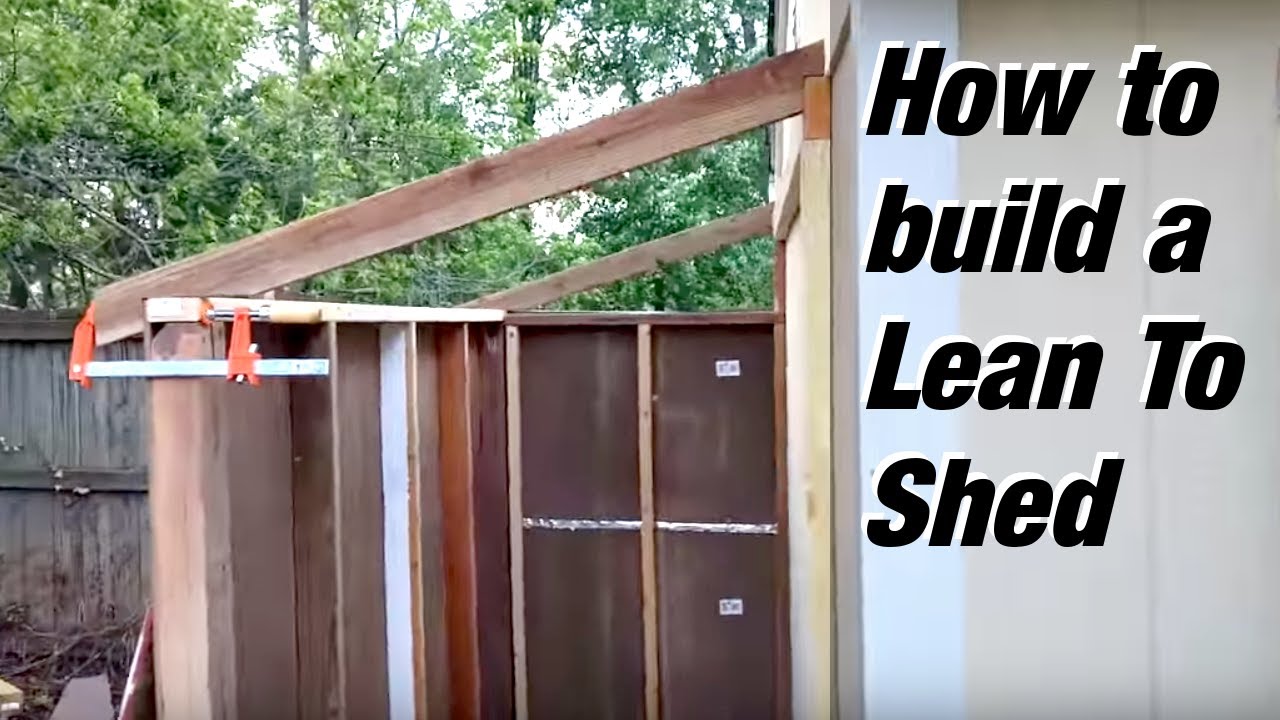

How to Build a Lean-to Shed

A lean-to shed is a simple addition that can add extra storage space and protection from the elements. Whether you want to use it as a workshop, storage shed or shelter for your garden tools, this type of project is easy to build and inexpensive.

The most common type of lean-to shed is open on one end and has two walls extending from the other side of your house. This allows you to attach the shed directly to your home and use it as an extension of your living space. The other side may be closed or open depending on how much access you want inside and what kinds of items you plan on storing in it.

If this is your first time building something like this, start out with these tips:

Measure twice and cut once. Use a measuring tape to take exact measurements from both sides of your house or garage so you know exactly how long each side needs to be. Use these measurements when cutting lumber so everything fits together perfectly.

Use treated lumber for siding if possible — treated lumber lasts longer than regular lumber, so it will require less maintenance over time (though still inspect regularly). If treated lumber isn’t available, consider using cedar

Building your own shed is a great way to save money. It’s also the perfect project for a weekend warrior. Most of the materials can be found at your local home improvement store and only basic construction skills are required.

Planning Your Project

When planning your shed project, determine what size you would like and where you want it located. Consider how much space you need as well as how it will fit into your outdoor space. Next, determine if you are going to build from scratch or purchase a kit with all the parts pre-cut for you. If so, make sure that all pieces will fit together properly before purchasing any materials or starting work on your project.

If you decide to build from scratch, collect all necessary tools and materials before starting work on the project. The most important tool is a good set of woodworking tools including measuring tape, saws (circular saw and table saw), power drill/driver, screwdriver/drill bit set (for driving screws), hammer and nails (metal or plastic). Other items that can be helpful include chalk line for marking straight lines on wood; carpenter’s level for making sure things are level; tarp or plastic sheeting to protect flooring while working; goggles or safety glasses