In this tutorial I will show you how to build stair stringers, how to build steps with blocks, and how to install deck stairs. This is part 1 of a 3 part series on how to build a set of stairs.

If you’re working on a project that calls for stairs be it someone wants a staircase in their home, the best way to build stairs (as I am sure you know) is with simple tools like a tape measure, level, square, circular saw and hammer.

How to build a set of stairs

Stair stringers. One of the most common methods is to build a stringer first and then nail it to the wall framing with metal hangers. The stringer can be made from 2x4s for a simple stairway or 2x6s for a more elaborate design. For an even more elaborate design, you can use 2x8s or even 2x10s.

Stair risers. The next step is to install the risers on top of the stringers using construction adhesive or other fasteners. You can also use metal brackets if you want your stairway to look more like a commercial staircase.

Steps with blocks. Another option is to build steps with blocks — such as concrete blocks or bricks — and attach them directly to the wall framing without any stringers at all. When attaching these blocks directly to the wall, use metal hangers instead of nails so they won’t pull out over time due to lateral forces from people walking up and down stairs (such as when children jump off the top step).

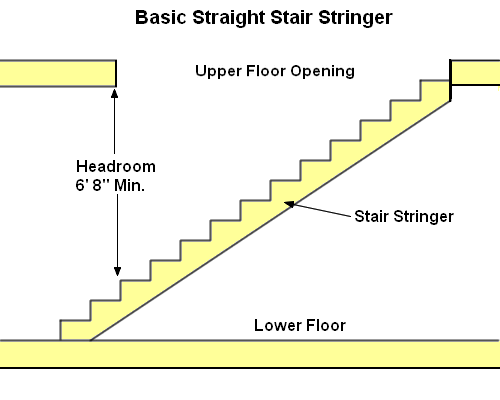

Stair Stringers

Stair stringers are the most important part of a set of stairs. The stringer is the main support beam that holds up the steps. Stair stringers are typically made from pressure-treated wood or dimensional lumber, but you can use other materials such as metal if you prefer.

When building your own deck, it’s best to use pressure-treated lumber for the stair stringers because it resists warping and rotting better than other types of wood. However, if you don’t have access to pressure-treated lumber, don’t worry — just be sure to protect your stringers with a good quality sealant or paint.

The length of your stair stringer will depend on how many stairs you want in your deck. It should be long enough to span at least two joists with enough room on either side for attaching the treads and risers (the horizontal parts) of your stairs. If you’re using pressure-treated lumber, make sure that there are at least 2 inches between each joist so that there’s enough space for attaching the treads and risers later on (a minimum distance of 3 inches is recommended for dimensional lumber).

After marking where each joist intersects with another joist — this will be

If you’re building a set of stairs, you will probably need to build the stringers first. The stringers are the framing members that support the steps. There are two types of stair stringers: open stringer and closed stringer.

You can build an open stringer by cutting the ends of 2x6s at 45 degrees, then nailing them together end to end. This can be tricky unless you have a good miter saw and plenty of space to work with it.

The easiest way is to use closed stringers that are pre-made at your local lumberyard. These come in 6-foot lengths and have predrilled holes for attaching them together with screws or nails. The only thing you’ll need to do is cut off their tops so they match your desired stair height

How to build stairs

Stair building can be a fun, simple way to add value and beauty to your home. The first step is selecting the right materials for your project. Then you need to know how to install each piece properly. Here are some basic steps for building stairs:

Materials

Stairs can be made from many different materials, including wood, steel and concrete. The material you choose depends on your budget, the style of your home and other factors. For example, wood is affordable and easy to work with but doesn’t hold up well outdoors. Steel is durable but expensive and heavy. Concrete can last for decades but isn’t always easy to install or repair if it cracks or breaks.

The stringer is a horizontal board at the bottom of each flight of stairs that supports the top treads and risers (the vertical parts) of the steps. It’s also known as a stringboard or understair stringer because it runs under each step rather than above it like most other components in a stairway system do. In many homes, you’ll find stringer boards attached underneath stair treads using screws or nails driven into predrilled holes in each side of those boards’ middle portions so that they

Building stairs is a fairly simple job, but it has to be done right. Here are some tips to help you make the right choices when building stairs.

Stair stringers are the main structural component supporting the treads and risers of your stairs. The typical stringer size is 2 x 8, but you can use 2 x 10 lumber as well, which will provide greater strength.

The best way to build stairs with stringers is to attach them to both sides of each step with a bolt-on hanger bracket. This ensures that the stringer won’t move out of position if one end sags more than the other during installation or after years of use and abuse.

Another option is to cut notches into the tops of the stair stringers so they fit snugly over the tops of each step riser. But this technique isn’t as secure or efficient as using hanger brackets because it requires more lumber and takes longer to install.

How to Build Steps with Blocks

Building steps is a simple project that can be done with a few tools and a little time. If you are building steps for a deck or porch, you will need to install them into the side of your home or into the ground. You should also consider how many stairs you want, as well as their height and width.

Steps come in different sizes, so if you need a custom staircase, make sure that you are able to get the right size before cutting it down. Also, if you want to build stair stringers yourself, make sure that they fit properly into your home before cutting them down.

Materials Needed:

Wooden blocks or 2x4s (depending on what kind of steps you want)

If you want to build stairs with blocks, it’s important to understand how to construct a set of stairs using them. There are several different methods of constructing steps using block, but all are based on similar principles. The first step is the most critical one: determining how many steps you’ll need and where they should go.

Steps are measured by their height and depth. The depth of a step varies depending on the materials used in its construction, but the standard depth for a concrete block step is 18 inches; this allows enough room for someone with boots on to get up and down easily.

The height of each step depends on the design of your staircase. In general terms, though, it’s best if each step is taller than it is wide. This makes it easier for occupants to navigate while wearing shoes or boots with heels or heavy soles that can slip on narrow stair risers (the sloped part between steps).

Stairs have two primary components: stringers and stringers. Stringers are solid pieces of wood (usually 2x12s or 2x10s) that run up the center of each flight of stairs; these serve as support for the treads and risers as well as providing a surface area for attaching handrails and

Stair stringers are the main structure or framework for steps. They are also called treads, landings, and risers. The stair stringer can be made from wood or metal. Many times, the stairs will have a combination of both materials.

Steps can be built in many different styles. It all depends on what the homeowner is looking for. Some people want their stairs to look like they came out of a magazine, while others just want something functional and affordable. The most important thing to remember when building your own steps is that they need to be safe and secure.

If you’re thinking about building your own steps, here are some helpful tips:

Prepare Your Area – Before you start building your steps, make sure that you have plenty of space and room around where you plan on putting them so that you don’t end up with any issues later on down the road when installing them into place.

Choose the Right Materials – When choosing materials for your stair stringer, there are several things that you need to consider before making your final decision on what material would work best for your project. These include cost effectiveness, ease of installation, durability and strength as well as aesthetic appeal

1. Lay out the stair stringer and mark the holes for the railing posts. The front edge of these posts should be flush with the front face of your stringer.

2. Using a hammer drill, bore a hole at each of these locations.

3. Set aside one of the railing posts and go back to drilling holes in your stair stringer for the block-and-spacer system that will support it.

4. Cut blocks of 2 x 4 to fit between your railing posts (see illustration). Space them along the length of your stairway so there’s at least 1/4 in between each one – more if you want a more open feel to your steps.

5. Position one block between each pair of posts (see illustration). It’s OK if they extend beyond the face of the post – it will help keep them stable as you build up other blocks around them later on.

Step 1: Lay out the stair stringer.

Step 2: Cut the stairs.

Step 3: Attach the stairs to the landing and floor.

Step 4: Install safety handrails on each step.

Step 5: Finish the staircase with a durable finish like polyurethane or varnish.